Sales

Alaska Seaweed InsightsThe seaweed market is a growing industry with exciting potential for the future. Although sales channels are still in the process of being established, hatcheries, farmers and processing facilities are working together to create a more streamlined and efficient value chain. Companies are actively exploring ways to take control of multiple stages or the entire value chain, fostering optimism for the market's growth. In response to the challenges faced, Alaska has seen the development of innovative marketing and sales strategies, bringing about opportunities for positive change within the industry.

An overview of kelp product types

- Food

- Raw Agricultural Product

- Food Ingredient

- Food Additive

- Dietary Supplement

- Agriculture

- Fertilizer

- Biostimulant

- Biopesticide

- Animal Feed/Additive

- Human Health

- Cosmetic

- Drug

- Fueld

Source: spoitzinc.ca/seaweed

Seaweed packaging at Kodiak Island WildSource

Seaweed from WildSource goes directly into a blast freezer truck to be delivered to Atlantic Sea Farms processing facility in Maine.

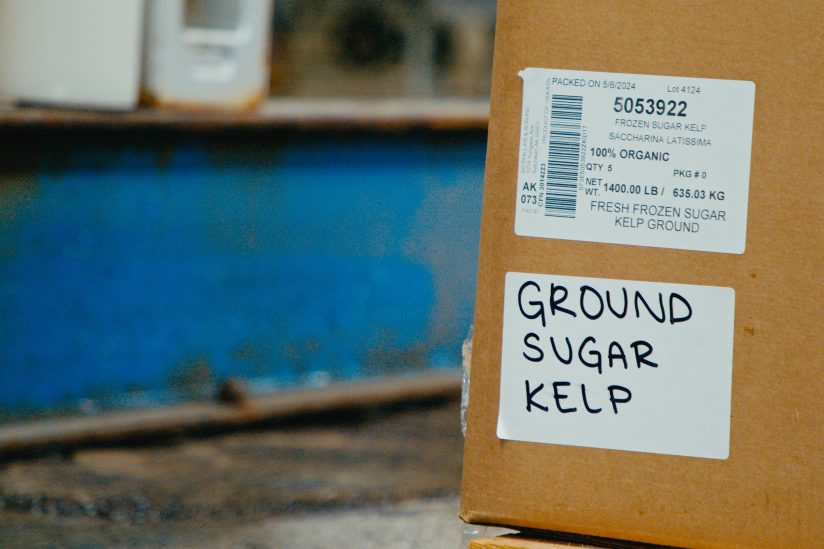

EC Phillips: ground frozen kelp

We need to get back to producing American-made seafood for our communities and the rest of America so they would have some of the best seafood in the world at their table. I believed that then, and I believe that now.

Product selection from Kachemak Kelp Hub

Barnacle Foods: product development and E-commerce

Case study Barnacle FoodsBarnacle Foods has developed its own consumer products and is selling them in its online shop.

So it's not a gimmick, it is mostly kelp, which is part of our marketing. Putting kelp into foods that are familiar, and people know how to eat, is a big part of our strategy.

Innovations & approach

- Barnacle Foods is dedicated to producing high-quality seaweed-based products, utilizing sustainably harvested kelp from both local farms and wild sources.

- The company's operations are organized to manage both direct consumer orders through their website and larger bulk orders for retail partners and distributors.

- The production process starts with stabilizing the wet kelp they receive from the farmers by grinding and blast-freezing it.

- The fronds of sugar kelp and bull kelp are primarily dried and processed into seasonings and crisps

- Meanwhile, bull kelp stipes are used to create sauces, including hot sauce, salsa, and barbecue sauce.

- Currently, Barnacle Foods has around 20 different SKUs and is looking for new products to develop.

- Barnacle Foods' products are in more than 1,100 shops in the US.

Joint Innovation Projects

Part of the AMC’s Research and Development Grant Component.

Cost-effective stabilization for transportation to market

A recent project aims to reduce the transportation costs for Alaskan kelp by 40 percent, by developing a new, cost-effective primary stabilization method using USDA-approved ingredients that eliminate the need for refrigeration. This innovation would not only make Alaskan kelp more competitive but also secure an immediate market opportunity for over 200,000 lb annually.

Decentralized processing for rural communities

This project aims to address the challenge of rapid seaweed degradation post-harvest by developing an open-source primary processing line for stabilizing kelp at ambient temperature near farms in rural Alaska. By offering accessible stabilization technology to rural kelp farmers, the project seeks to prolong the shelf life of seaweed products, enabling better market access and enhancing the industry's sustainability through innovation.

Four approaches to small-scale primary seaweed stabilization

This project aims to tackle the challenge of primary processing at the community hub and small farm collective scale (10-30 acres) by tailoring processing methods to local contexts and end-product markets.

Building on existing partnerships and leveraging funding, the project will involve collaboration with partners such as APMI, Alaska MEP, the University of Alaska, and Salmon Sisters. Additionally, by engaging with the Alutiiq Pride Marine Institute and the communities of Port Graham and Nanwalek, the project will focus on testing and learning processing methods that align with community needs, fostering innovation in processing techniques and value-added product development within the local industry.

Marketability and production protocols for kelp-based wine and spirits

This innovative project aims to pioneer kelp wine and spirit production by addressing the need for more information and market studies in this area. By consulting enology and marketing experts, the project seeks to uncover optimal production processes, including fermentation, stabilization, and bottling, as well as identify potential markets for these unique products. With the Alaskan kelp industry in its early stages, the project not only aims to create environmentally friendly products but also to open new markets for local growers, fostering business expansion and economic growth.