The unique site conditions determine the type of equipment needed on a seaweed farm. The design needs to reflect the marine physical conditions of the farm, the type of species being grown, the technology available for seeding and harvesting, and the need to fit within the existing use and regulatory framework. Anchors, ropes, cultivation lines, floats, and buoys are essential gear for all marine cultivation designs. The equipment and materials the farmer chooses for each will depend not only on the site conditions but also on the price and availability of the equipment.

General characteristics of Alaskan seaweed farms

- Cultivation method

- Horizontal grid, long lines

- Design system

- Single-line array, five-line array, catenary array

- Distance between cultivation lines

- 2.8 ft - 10 ft

- Depth of line

- ~10 ft for sugar kelp, 6 ft for bull kelp

- Spreaderbar

- Metal / wood

- Culture line

- Nylon ropes

- Anchor

- 700-800 pound anchors

-

Depending upon the system

- Floater

- Plastic buoys

- Boat

- Motorized boat

Kelp farming is typically conducted nearshore, with adequate water depth, as farmed kelp can grow up to 15 feet. Alaskan kelp farmers utilize three main systems tested and adopted from other kelp farming regions across the globe.

Single-line array system

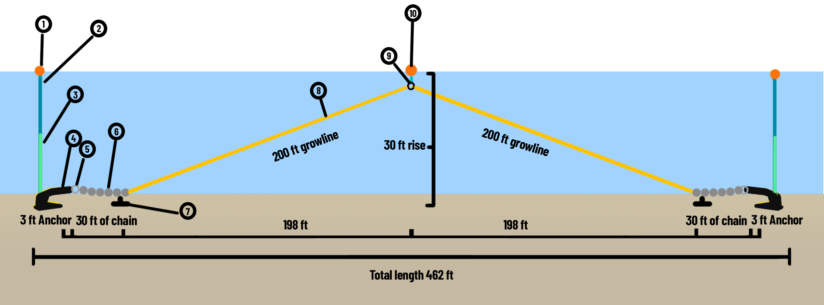

The single-line array is the simplest method for growing kelp and has been used for decades. It consists of a single horizontal growline, submerged several feet below the surface and wrapped with seed string, anchored at both ends. The single-line array does not require large anchors or complex floatation systems like the 5-line or catenary systems. As a result, it is well-suited for smaller operations or for those who are new to kelp farming.

Five-line array system

The five-line array is an advanced version of the single-line array. It uses spreader bars to hold multiple grow lines closely within the same system. This design increases the number of grow lines per pair of anchors, boosting farm capacity without expanding the site footprint. In contrast to single-line arrays, the five-line array attaches flotation buoys to the spreader bars via bridles rather than directly to the growing lines. It is crucial to maintain even tension throughout the system for stability. Drag embedment anchors, adjustable once in the water, help keep the system under constant tension. The five-line array offers significantly higher production without overextending the farm's footprint.

We participated in several workshops where we learned how to build and deploy these five-line arrays. We ultimately chose this design because it's straightforward to construct and easy to deploy, making it a practical option for our needs.

Catenary array system

The catenary array is the most complex type of kelp farming system. Unlike simpler arrays that use two anchor points, the catenary array secures a matrix of closely spaced grow lines with fewer, but larger, anchors at the corners. These anchors are connected by curved horizontal lines, known as catenary framing lines, which secure the grow lines. This system can accommodate up to 55 lines spaced only a few feet apart. Due to its size and capacity, it requires significantly larger anchors and buoys compared to simpler systems. For example, a farm in Kodiak uses pairs of 800-pound anchors at each corner. A catenary array can produce several hundred thousand pounds of kelp on a single site. However, this system demands a thorough understanding of local nutrient levels, as many areas may not support such high biomass.

Seaweed density and buoyancy considerations

A key challenge is finding the right balance between maximizing available water space for seaweed farming and preventing the kelp from competing with each other for light and nutrients, which can slow down their growth. It's also important to consider that different types of seaweed require different farming systems. For example, ribbon kelp and sugar kelp are sinking seaweeds that need buoys to keep them close to the surface, while bull kelp is a floating seaweed that needs weights added to optimize space usage. Farmers are currently experimenting to determine the best depth and spacing for seeding the growing lines for each type of kelp.

Pioneering two designs for bull kelp farming

Case study Sea Quester Farms LLCInnovations & approach

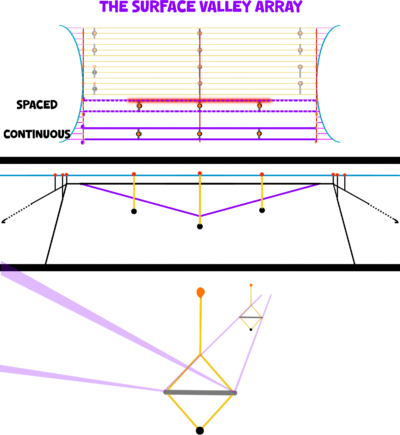

When comparing suspended arrays with benthic arrays, it is believed that benthic arrays, being attached to the seafloor, can better mimic the natural conditions of bull kelp in the wild. This is because they allow the tide to come down and meet them twice a day rather than being tethered to the surface and maintaining the same minimum depth all day.

Using a weight in the middle of the line creates a V-shaped design to evaluate growth along the line at different depths with seasonal variability. Illustration credit: Jonny Antoni, Sea Quester Farms

The benthic array is designed with one buoy in the middle of the growline, simulating the natural growing conditions. Illustration credit: Jonny Antoni, Sea Quester Farms

Greenwave is providing an interactive Ocean Farm Design Tool to support early-stage ocean farmers in getting a head start on designing farms, gear lists, and budgets.

Equipment

Farmers use a wide variety of equipment and gear to maintain their kelp farm. Much of the equipment can be repurposed from other farms or the fishery industry, but it needs to be designed and assembled differently. The key aspects of the design are utility for maintenance and harvesting, as well as effective use of space. When setting up, ensuring the proper tension of the lines is a challenging part of any farm design. It's essential to figure out how to make sure the lines are stable but flexible enough to withstand storms and avoid becoming entangled with each other.

Grow line buoys

It is essential to keep kelp afloat as it grows. As sugar kelp becomes heavier, it can weigh down the growing line, potentially causing it to sink. The growing line buoys counteract this by maintaining the kelp at an optimal depth of 5-6 feet below the surface. They also provide an access point for farmers to lift the grow lines and inspect the kelp without disrupting its growth. A 200-foot grow line typically uses three buoys spaced 50 feet apart.

Spreader bar

In a typical five-line array, the spreader bar is a 10-foot-long, 3-inch-diameter aluminum pipe with welded eyes for line connections. Positioned on either end and at 100-foot intervals along the growing, spreader bars hold five parallel lines at a fixed distance apart.

Common seaweed farming equipment

Anchors, ropes, culture lines, floats, and buoys are essential basic equipment for all sea-based seaweed farm designs. The equipment and materials the farmer chooses will depend not only on the site conditions but also on the price and equipment's local availability.

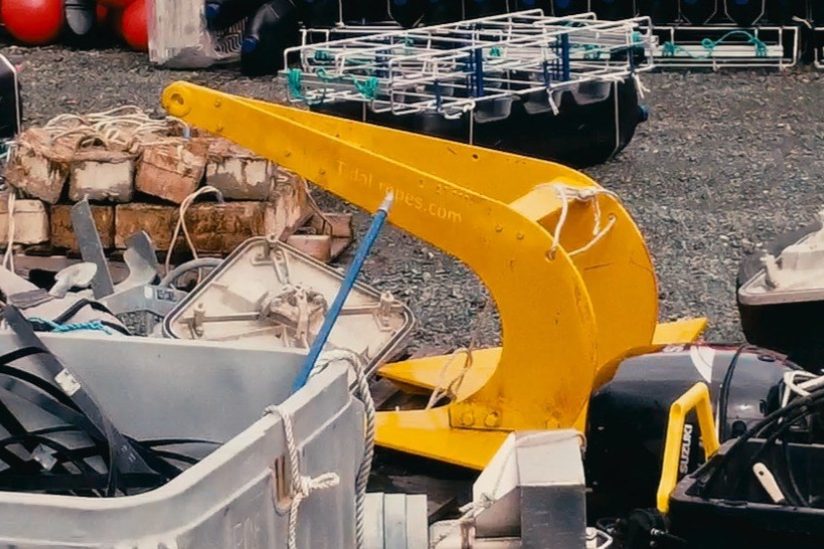

Anchors

Anchors secure the array to the seafloor, maintaining its position and tension. They are connected to the growing line by an anchor line, and sometimes a length of chain, collectively called the anchor rode. Tensioning buoys along the anchor line helps maintain tension during tidal fluctuations by rising in the water at low tide. Tag lines run from the anchor to a retrieval buoy on the surface, keeping the anchor in place for retrieval or tensioning.