Hatchery

Alaska Seaweed InsightsA widespread, high-quality network of kelp hatcheries can serve as the foundation for developing a robust and scalable seaweed industry in Alaska. Ongoing effective collaborations between research institutes and commercial hatcheries in different regions of Alaska are improving propagation protocols. This contributes to local biodiversity conservation and increases industry efficiency, productivity, and sustainability.

According to ADFG analysis, 299,000 feet of seeded line were sold in 2022, followed by 233,100 feet in 2023, representing a 22% decrease. This decrease correlated with lower production reported by hatcheries in 2023. Sales of seeded line for growing seaweed also fell in 2024. Despite declining seed sales in 2024,

seaweed harvest is expected to increase to 400,000 pounds in 2025 based on higher yield expectations.

A hatchery is a facility designed to initiate species reproduction and support young seaweeds' early growth before it is transfered to sea. In Alaska, the process begins in with the collection of spore-rich sorus tissue, usually the top part of the kelp, from August to October.

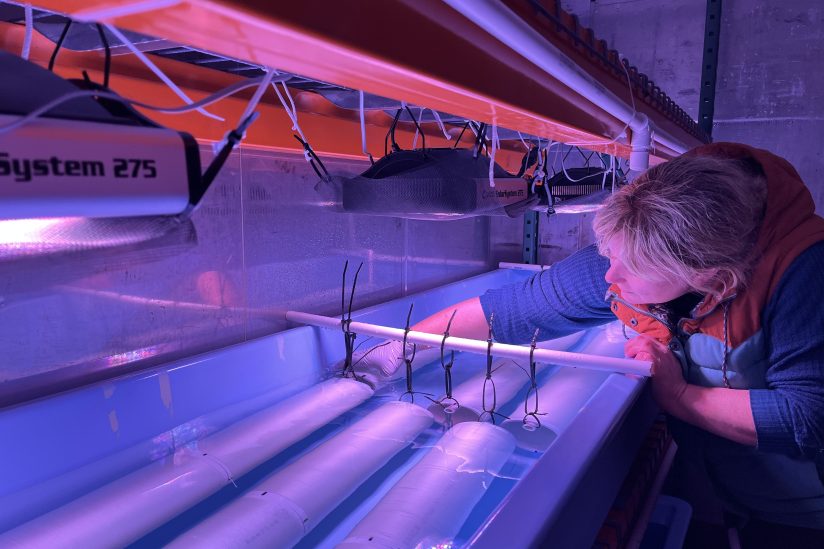

In a controlled environment, with specific light, temperature, and nutrients, spores settle on strings wrapped around PVC spools. These spores develop into juvenile sporophytes, which eventually grow into adult kelp. Hatchery operators in Alaska manage the collection, spore extraction, and maintenance of culture tanks to ensure the healthy development of the kelp.

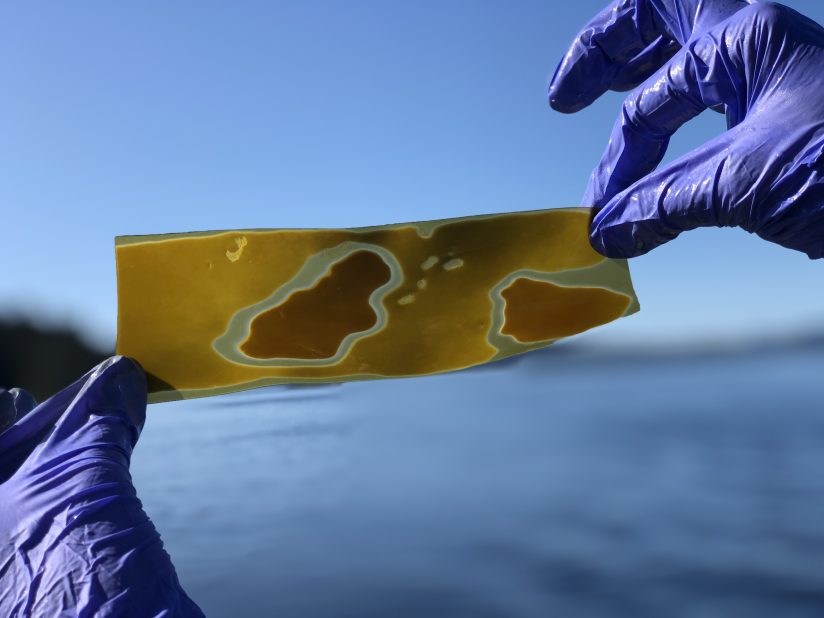

Spore-rich sorus tissue on kelp

Credit: Seagrove KelpThe primary season includes the cultivation and winter outplanting of the seed spools, typically done around November, after around 6 weeks of growing in the hatchery. Commercial hatcheries must produce consistent, high-quality seedlings in sufficient quantities to meet farmers' needs. Different seaweed species may require different methods for growing seedlings - such as grafting into longlines, isolating the tip for starter cultures, or culturing and breeding gametophyte stocks, which eventually become juvenile sporophytes and grow into full-sized adult kelp.

The continuous efforts of existing hatcheries to adapt to Alaska's unique features and landscape ensure a resilient and reliable supply of seeds. These diverse and creative setups and adjustments in hatchery operations aim to provide a consistent supply of seeds of a range of species with desirable traits such as fast growth rates and disease resistance.

There is potential for Alaska’s researchers and regulators to reexamine the 50/50 rule and allow gametophyte seed bank cultivation. This could relieve some hatchery-related bottlenecks. For example, farmers wouldn’t have to dive for sorus tissue every year and clear up other challenges stemming from the 50-50 requirements. In April 2024, Alaska Sea Grant and AFDF hosted the Alaska Seaweed Genetic Workshop, addressing some of these issues.

Using shipping containers for modular hatcheries

Case study Alaska Ocean Farms LLCThe use of 40-foot shipping containers allows for multiple cycles to be run if there is demand.

In the video below Lexa Meyer from Alaska Ocean Farms provides a comprehensive list of the necessary equipment and materials for setting up a hatchery.

Innovations & approach

In the video below, Lexa Meyer from Alaska Ocean Farms provides an overview of her hatchery setup concept.

A hatchery is an incredibly simple system. A hatchery needs just a few things to be successful. To grow kelp you need water, nutrients, light, and temperature control

Notable features

- It has a comparatively low cost: around $140,000 per system.

- It can be deployed in various locations across Alaska, including remote ones, which eliminates the risks of transporting spools to distant areas.

- The system has a base capacity of producing 200,000 feet of seed line. When there is demand, it can run two cycles from August to mid-October, and then start again to be ready for a late November or early December deployment, resulting in a total production of 400,000 feet each season.

- The system is flexible and allows for constant improvements, such as identifying the best practices for quality spools, the best density of sporophytes by species, and the optimal seed spacing.

On-vessel mobile hatchery

Case study Mothers of Millions LLCThis is a great example of how to utilize commercial fishery assets during the off-season and apply fishing experience, expertise, equipment, and technical know-how to enhance and expand seaweed cultivation operations.

Innovations & approach

Advantages

- Underutilized commercial fishing assets can be repurposed for seaweed cultivation.

- Leveraging existing fishing expertise, equipment, and technical know-how can help improve and expand seaweed farming operations.

- Overcoming the impact of regional weather conditions on supply chains can improve accessibility and flexibility for the industry, especially in remote locations.

- Adhering to the 50-50 Rule means that source tissue can be collected and handled immediately on board. Bringing seeding spools directly from the hatchery to the farm can minimize problems associated with handling and transporting seed material.

- The hatchery only requires one person to operate it for a few hours per week.

- The mobile hatchery was designed to be used at the end of the summer salmon fishing season. With the hatchery aboard, samples can be collected and processed on the way back to port.

The efficiency and yield at the farm are critical, because if you do not get maximum survival rates and production based on your seeds, all the OpEx costs change.

R&D and innovation

Research can solve functional problems and contribute new knowledge, processes, technology, and innovation to Alaska's growing seaweed industry. Partnering with farmers, hatcheries, and other partners in applied research is critical for the industry's growth and for effectively leveraging research funding.

How R&D can support sustainable practices

Tamsen Peeples, a master's student at the University of Alaska Fairbanks in Juneau, is conducting experiments to improve commercial seaweed hatchery protocols. She is collaborating with Sea Quester Farms to find a natural replacement for the synthetic string currently used for kelp seeding lines, which needs to be removed from the long lines after harvesting, and causes significant labor and environmental issues. The goal is to identify a natural fiber, such as cotton, silk, or hemp, that can last long enough for the migration of the sporophyte to the main grow line but then dissolve. This ongoing research aims to find a suitable replacement to reduce labor, expenses, and waste.

R&D and industry partnerships

Case study OceansAlaska and SeagroveOceansAlaska is a non-profit marine science and hatchery enterprise that has partnered with Seagrove since 2019 to produce kelp and shellfish seed. Their goal is to provide workforce training and conduct various experiments to enhance kelp spawning. The collaboration showcases the synergy between non-profit and for-profit industries working together to develop the seaweed sector.

Innovations & approach

Notable features

- The equipment in the OceansAlaska facility is owned by Seagrove and jointly operated by the two companies.

- Strict biosecurity protocols involve sterilized seawater and ongoing rack disinfection during production to prevent the growth of unwanted organisms.

- Each rack has a separate piping system, which allows the cultivation of seeds from different locations or different species simultaneously without the risk of cross-contamination.

- It includes an in-house wet lab for kelp reproduction by handling sorus tissue, isolating kelp spores, and supporting the early growth of young kelp plants (sporophytes).

Commercial and R&D hatchery: A hub for seed supply, mariculture research, community engagement

Case study Prince William Sound Science and Technology InstituteThe Prince William Sound Science Center (PWSSC) is a research and education institute focusing on ocean-related topics, including mariculture. As part of multiple mariculture R&D projects designed to address key challenges and support the industry's growth, it also operates a kelp hatchery, which supplies kelp to local farmers. PWSSC also emphasizes local community engagement, running workshops, theme-based education programs, and summer programs to educate people on mariculture.

Innovations & approach

Notable features

- Mariculture R&D: PWSSC runs multiple projects that facilitate the growth of the mariculture industry in Prince William Sound, including the annual Kelp the Sound workforce development workshop series, evaluating best practices for harvesting seed stock, the Mariculture Research and Restoration Consortium (Mariculture ReCon), researching the use of excess diesel power plant heat to dry kelp, and more.

- Commercial Hatchery and Seed Quality Research: With a state-of-the-art new hatchery installed in spring 2025, PWSSC operates an ADNR and ADF&G-permitted commercial seaweed hatchery, which provides hatchery services to seaweed farmers in Prince William Sound and conducts research to identify best practices for hatcheries.

- Community Education and Engagement: PWSSC's education department offers theme-based education programs for learners of all ages. It runs a "sea squirts" program with kelp touch tanks for children, and a "Tuesday Night Talk" lecture series where researchers and community members can share their projects, including those related to kelp and mariculture.

The people are what are driving this. What brought this far are the farmers, the people who want to support the industry. And that's what could make it work: we have these wonderful, hardworking people who won't say no or quit.