Harvesting kelp in Alaska requires careful timing to maximize quality and yields. Farmers face challenges such as balancing rapid growth during sunnier days in April and May with the increased biofouling risk. Additionally, they must consider harvesting vessels' availability, distance to processing facilities, and weather conditions. Several harvesting techniques and technologies are being developed to ensure efficient and effective harvesting.

Biofouling on seaweed refers to the settlement and development of unwanted aquatic species on the seaweed's surfaces, such as Epiphytes, Tunicates, and Bryozoans. The effects of biofouling include the loss of commercial value, decreased productivity due to breaking fronds, and reduced growth due to limited nutrient uptake and restricted light availability. Furthermore, fouling organisms on infrastructure (ropes and rafts) used to culture seaweeds can cause infrastructure to sink below the surface, requiring labour-intensive cleaning.

Harvesting processes

In Alaska, kelp farmers use various techniques to efficiently harvest seaweed, depending on the size of the boat or the number of people available. They use mechanical aids such as cranes or winches to help position the lines and make the cutting process faster and more precise. Affordable tools like grappling hooks on ropes are often used to access the lines without needing heavy-duty permanent attachments. More extensive operations might use claw attachments for cranes.

After cutting, the seaweed either falls into tote tanks or bags. The choice of containers, ranging from fish boxes and bags to folding pallet boxes lined with food-safe plastic, depends on transportation needs and available mechanical handling equipment. Sealed containers protect the seaweed from drying out in warm conditions or soaking in freshwater during rain, ensuring better quality upon arrival at the processing facility. Tote bags allow the cut seaweed to be placed back in the water, protecting it from damage. The goal is to keep the seaweed fresh and undamaged during transit.

Working at sea is much more costly than working on land, so it needs to be done quickly and efficiently. Factors impacting harvest rates include infrastructure design, yield per meter of grow line, farmers' experience, unexpected challenges, weather conditions, and levels of mechanization. The infrastructure design should consider the accessibility of grow lines and ease of navigation.

It's going to cost you X amount of dollars to charter that boat to harvest kelp, whether it's 10,000 pounds or 200,000 pounds. Therefore the efficiency and the yield that you can harvest at your or other farms is critical.

Harvesting time

The best time to harvest kelp is during dry and cool weather, as rain can cause blistering on the kelp, while heat can rapidly degrade the quality.

The perfect conditions for harvest are:

- Tide ebbing and close to low water: This provides slack in the lines, making them easier to lift.

- Calm seas: This reduces the risk of tangling lines while lifting them, making the job safer and more efficient, and requiring fewer labor hours per unit of kelp harvested.

- Cloudy weather: This helps maintain the quality of the kelp.

- Temperature between 32°F and 50°F: This helps maintain the quality of the kelp.

Equipment to use

For Alaskan kelp farmers, proper equipment is essential for efficiently and safely handling the harvest.

Examples of tools and equipment:

For the most part we've been really lucky in that we've been able to avoid the biofouling simply by timing the harvests. So getting out here at the sweet spot of the season when we've had sort of maximal growth before we have snails, eggs, and other things setting up shop.

Harvest Buddy: an off-grid portable harvest platform

Case study Alaska Ocean Farms LLCHarvest Buddy is a stand-alone harvesting platform that can be easily transported for efficient harvesting in different locations, moving along by the hydraulic pull of the cultivation line.

It was developed with funding from the US Department of Energy's ARPA-E program and is also used as a training tool for seaweed farmers nationwide.

Innovations & approach

Notable features

- Can be easily transported for efficient harvesting in various locations.

- Eliminates the challenges of working from within a small boat.

- No need for heavy lifting by hand, reducing safety concerns.

- Low carbon footprint, as it doesn't require a gas engine.

- Space-efficient, as there's no need to store biomass on the deck.

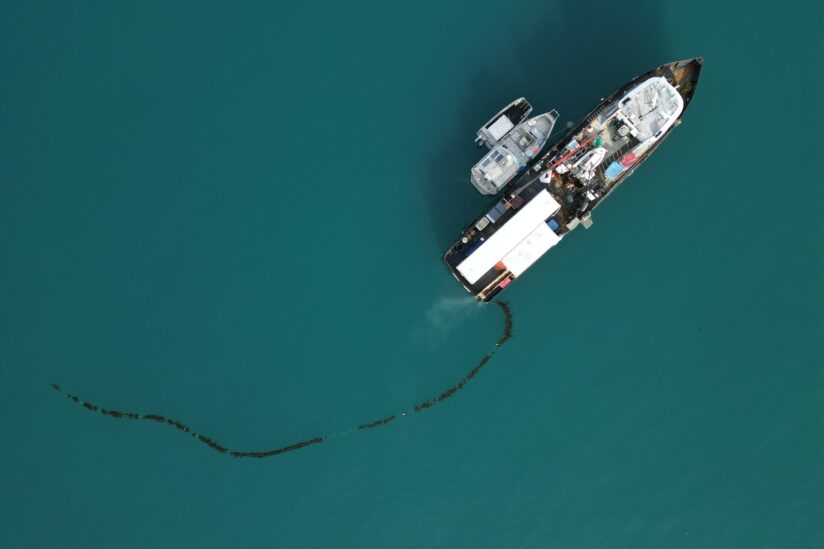

Fishing boat mobile harvesting platform

Case study Mothers of Millions LLCMothers of Millions built a mobile harvesting station on a fishing boat that is used during the offseason. They use their fishing experience, equipment, and technical know-how to improve and scale seaweed cultivation operations creatively.

Innovations & approach

Notable features

- Repurposing fishing and vessel machinery, such as a hydraulic power unit, to support pulling in biomass-heavy culture lines to the harvester.

- Experimenting with harvesting the culture lines with the kelp (instead of cutting the kelp off the line) and keeping it in cooled tanks at 38°F on board (in the fish holds). This enables the harvesting of an entire farm in a day reducing costs and risks associated with being on the water.

- Locating a freezer container on the deck next to the harvester so that biomass can be immediately stabilized and stored in ~1,000-pound shredded kelp trays for easy handling, according to specific volume needs.